Glass fiber concrete

Glass fiber concrete

Glass fiber concrete is glass concrete, it is a type of artificial stone obtained by dispersed reinforcement of cement concrete with fiber. Known as glass fiber concrete, or grc. This material appeared in the 70s of the last century and has not lost its relevance to this day.

Fiberglass concrete is a composite material and at the same time combines the inherent properties of cement mortar, high compressive and impact strength, increasing by 10-12 times (due to fiberglass reinforcement), and 4-5 times increased bending and tensile strength.

Comparison of the strength of cement-sand mixtures

No. P/p material bending strength mpa (kgf/cm2)

1 cement-sand mixture without fiber 40-50 mpa (400-500 kgf/cm2)

2 grc spray mixture 200 mpa (2000 kgf/cm2)

3 grc mixture "premix" 120 mpa (1200 kgf/cm2)

The main component of fiberglass concrete is largely determined by its unique properties - it is glass fiber, which acts as a reinforcement in the concrete matrix. It is well known that glass fibers have a high tensile strength, due to which it is widely used for reinforcement and such composite materials as fiber-plastic based on epoxy resins.

Alkali-resistant glass fiber produced by nippon elektrik glass, in japan, isare used in production process.

GRC products are obtained by the method of pneumatic spraying, by synchronous spraying through a special gun of fine-grained concrete mixture (cement-sand mortar) and alkali-resistant chopped fiberglass, the advantage of this technology is that it is possible to make large-sized products with an application area of up to 20 m2. This method is also suitable for the production of construction and architectural products of small and medium sizes, with an area of up to 2 m2.

Notes:

Grc shell (spray), the main structural element of the products, is made by the method of pneumatic spraying with simultaneous mixing of crushed glass fiber. Main characteristics:

- bending strength – 200 mpa;

- frost resistance – 200 cycles;

- application thickness – 10-50 mm.

"Premix" is an auxiliary structural element of products (in some types of products it is the main element) obtained by the method of introducing chopped glass fiber "roving" into a ready-made cement-sand mortar main characteristics:

- bending strength – 12 mpa;

- frost resistance – 200 cycles;

- application thickness – 10-250 mm.

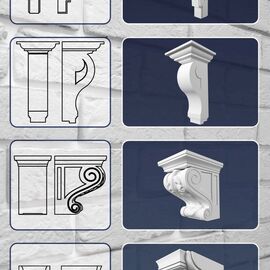

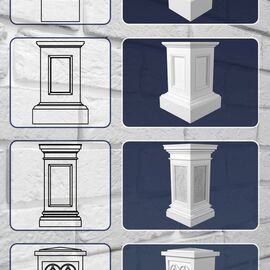

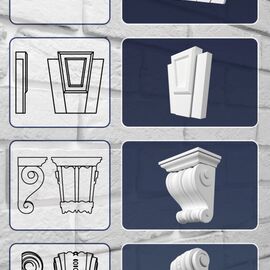

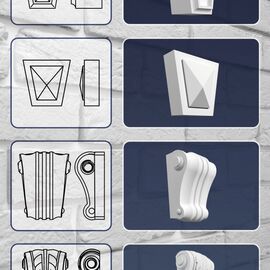

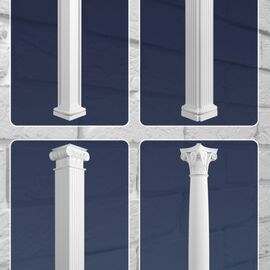

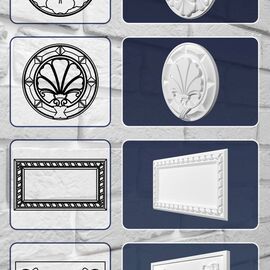

Products and design schemes

AFB Aspect’s production facilities provide, a full cycle of manufacturing the following types of products:

- external wall panels made of fiber concrete are insulated;

- external wall panels are not insulated on the frame and without;

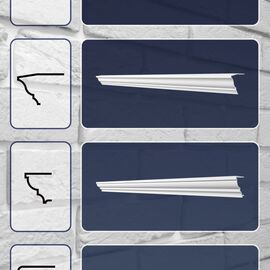

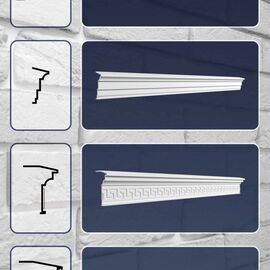

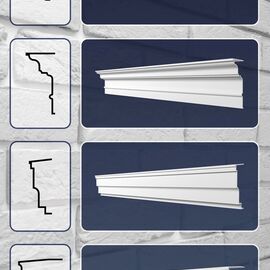

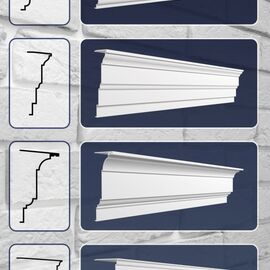

- cornices and decorative elements;

- external and internal wall panels for prefabricated reinforced concrete buildings.